首页 > 除湿干燥机系列 > 文章内容

首页 > 除湿干燥机系列 > 文章内容

![]()

PET/PETG /PLA/PMMA/PCCRYSTAL DRYING SYSTEM

PET/PETG/PLA/PMMA/PC

树脂挤出成型结晶干燥系统

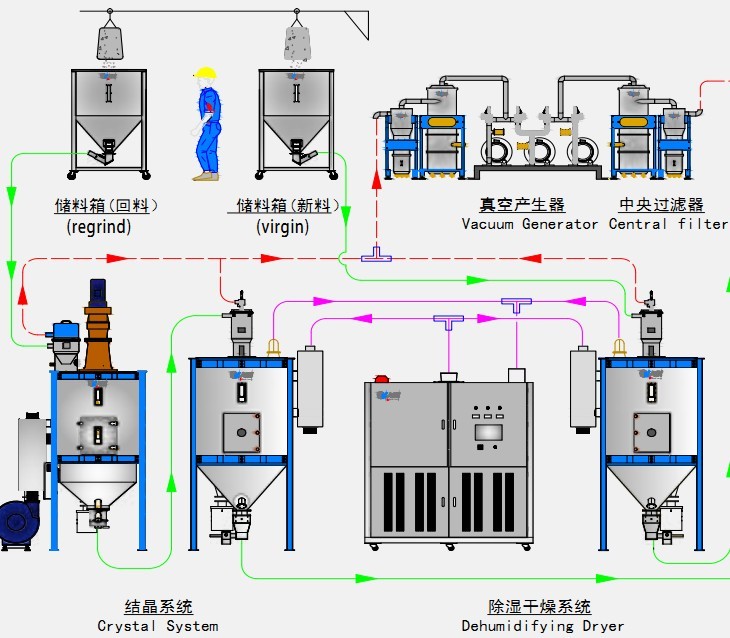

尼嘉斯的结晶及干燥系统设备以丰富的干燥技术、程序化的电脑控制技术以高性能的机械技术为基础,高效地解决片材的挤出生产过程中所产生的片材脆化、含水分解、粘度降低、酸性劣化等品质问题。

The NIASI crystal&drying system equipment is built on experienced drying technology,programmed computer control and high performance of mechanical technology, which efficiently solves the problems e.g. sheet orpiece brittleness, resolve with water, reduce of viscosity and degradation of acid etc. during the plastic extrusion processing course.

尼嘉斯的结晶、干燥系统设备以人性化设计为基础操作使用、保养快捷简便确保挤出生产线连续稳定地提供干燥完成的树脂原料。

The NIASI crystal&drying system equipment with humanized designed which can easy and efficient assure the supply of dried resin material incessantly and steadily.

尼嘉斯的树脂结晶、干燥系统设备要求对温度、风量、风压、输送时间等系统参数进行在线高精度控制、并使用系统内交互热能充分利用、大幅度降低了能耗。系统过滤装置可高效过滤原料中的粉尘,确保制品的品质稳定。

The NIASI crystal&drying system equipment requires for high precisely control of the air temperature, volume, pressure and feeding time etc.and fully use of the internal heat energy which can greatly reduce the consumption of energy power. Also the filter equipment could efficiently reduce the powder or duster in material this highly helps to keep the high quality of the products.

干燥能力参照表 Specifications for Drying Capacity

| 原料 | 干燥 温度 | 干燥 时间 | 比热 | 原料 比重 | 除湿 前含 水率 | 除湿 后含 水率 | 干燥能力 | ||||||||||||||

| ND-30 | 50 | 80 | 120 | 150 | 200 | 300 | 400 | 500 | 700 | 1000 | 1500 | 2000 | 3000 | 4000 | |||||||

| ABS | 80 | 2-3 | 0.34 | 0.6 | 0.3 | 0.02 | 11 | 18 | 27 | 35 | 71 | 200 | 180 | 210 | 285 | 355 | 425 | 710 | 1065 | 1500 | 1600 |

| CA | 75 | 2-3 | 0.5 | 0.5 | 1 | 0.02 | 9 | 15 | 22 | 30 | 60 | 105 | 150 | 180 | 235 | 295 | 355 | 590 | 885 | 1200 | 1330 |

| CAB | 75 | 2-3 | 0.5 | 0.5 | 0.8 | 0.02 | 9 | 15 | 22 | 30 | 60 | 90 | 150 | 180 | 235 | 295 | 355 | 590 | 885 | 1200 | 1330 |

| CP | 75 | 2-3 | 0.6 | 0.6 | 1 | 0.02 | 11 | 18 | 27 | 35 | 71 | 90 | 180 | 210 | 235 | 355 | 425 | 710 | 1060 | 1500 | 1600 |

| LCP | 150 | 4 | 0.6 | 0.6 | 0.04 | 0.02 | 8 | 13 | 20 | 27 | 55 | 106 | 135 | 160 | 210 | 265 | 320 | 530 | 800 | 1150 | 1200 |

| POM | 100 | 2 | 0.35 | 0.6 | 0.2 | 0.02 | 16 | 27 | 40 | 53 | 105 | 80 | 265 | 320 | 425 | 530 | 640 | 1060 | 1600 | 1800 | 2400 |

| IONOMER | 90 | 3-4 | 0.55 | 0.5 | 0.1 | 0.04 | 7 | 11 | 17 | 22 | 44 | 160 | 111 | 133 | 177 | 220 | 265 | 442 | 663 | 750 | 1000 |

| PA6/6.6/6.10 | 75 | 4-6 | 0.4 | 0.65 | 1 | 0.05 | 6 | 10 | 14 | 19 | 38 | 66 | 96 | 115 | 153 | 192 | 230 | 383 | 575 | 960 | 1040 |

| PA11 | 75 | 4-5 | 0.58 | 0.65 | 1 | 0.05 | 7 | 12 | 17 | 23 | 46 | 58 | 115 | 138 | 184 | 230 | 275 | 460 | 690 | 780 | 1150 |

| PA12 | 75 | 4-5 | 0.28 | 0.65 | 1 | 0.05 | 7 | 12 | 17 | 23 | 46 | 69 | 115 | 138 | 184 | 230 | 275 | 460 | 690 | 780 | 1150 |

| PC | 120 | 2-3 | 0.28 | 0.7 | 0.3 | 0.01 | 13 | 21 | 31 | 41 | 83 | 69 | 206 | 250 | 330 | 413 | 495 | 826 | 1238 | 1400 | 1860 |

| PU | 90 | 2-3 | 0.45 | 0.65 | 0.3 | 0.02 | 11 | 19 | 29 | 38 | 77 | 124 | 190 | 230 | 307 | 383 | 460 | 767 | 1150 | 1530 | 2080 |

| PBT | 130 | 3-4 | 0.3-0.5 | 0.7 | 0.2 | 0.02 | 9 | 15 | 23 | 31 | 62 | 115 | 155 | 186 | 248 | 310 | 372 | 620 | 930 | 1100 | 1600 |

| PE | 90 | 1 | 0.55 | 0.6 | 0.01 | <0.01 | 32 | 53 | 80 | 106 | 212 | 93 | 531 | 637 | 850 | 1065 | 1275 | 2125 | 3185 | 3600 | 4800 |

| PEI | 150 | 3-4 | 0.6 | 0.6 | 0.25 | 0.02 | 8 | 13 | 20 | 27 | 53 | 318 | 133 | 160 | 212 | 265 | 320 | 530 | 800 | 1030 | 1370 |

| PET | 160 | 4-6 | 0.3-0.5 | 0.85 | 0.2 | 0.05 | 8 | 13 | 19 | 25 | 50 | 80 | 125 | 150 | 200 | 250 | 300 | 500 | 750 | 1150 | 1360 |

| PETG | 70 | 3-4 | 0.6 | 0.6 | 0.5 | 0.02 | 8 | 13 | 20 | 27 | 53 | 75 | 133 | 160 | 212 | 265 | 320 | 530 | 800 | 1030 | 1370 |

| PEN | 170 | 5 | 0.85 | 0.85 | 0.1 | 0.05 | 9 | 15 | 23 | 30 | 60 | 90 | 150 | 180 | 240 | 300 | 360 | 600 | 900 | 1150 | 1360 |

| PES | 150 | 4 | 0.7 | 0.7 | 0.8 | 0.02 | 9 | 15 | 23 | 30 | 60 | 90 | 150 | 180 | 240 | 630 | 360 | 600 | 900 | 1050 | 1400 |

| PMMA | 80 | 3 | 0.65 | 0.65 | 0.5 | 0.02 | 11 | 19 | 29 | 38 | 77 | 115 | 190 | 230 | 310 | 385 | 460 | 765 | 1150 | 1530 | 1730 |

| PPO | 110 | 1-2 | 0.4 | 0.5 | 0.1 | 0.04 | 13 | 22 | 33 | 44 | 88 | 133 | 220 | 265 | 355 | 440 | 530 | 885 | 1330 | 1730 | 2660 |

| PPS | 150 | 3-4 | 0.6 | 0.6 | 0.1 | 0.02 | 8 | 13 | 20 | 27 | 53 | 80 | 133 | 160 | 212 | 265 | 320 | 530 | 800 | 1030 | 1370 |

| PU | 120 | 2 | 0.27 | 0.6 | 0.4 | 0.02 | 16 | 27 | 40 | 53 | 105 | 160 | 265 | 320 | 425 | 530 | 640 | 1060 | 1600 | 1800 | 2400 |

| PP | 90 | 1 | 0.46 | 0.5 | 0.1 | 0.02 | 26 | 44 | 66 | 88 | 180 | 265 | 442 | 530 | 710 | 885 | 1060 | 1770 | 2655 | 3500 | 4000 |

| GP(GP) | 80 | 1 | 0.28 | 0.5 | 0.1 | 0.02 | 26 | 44 | 66 | 88 | 180 | 265 | 442 | 531 | 708 | 885 | 1062 | 1770 | 2655 | 3500 | 4000 |

| PSU | 120 | 3-4 | 0.31 | 0.65 | 0.3 | 0.02 | 8 | 14 | 22 | 29 | 60 | 85 | 145 | 173 | 230 | 290 | 345 | 575 | 865 | 1300 | 1485 |

| PVC | 70 | 1-2 | 0.2 | 0.5 | 0.1 | 0.02 | 13 | 22 | 33 | 44 | 90 | 135 | 220 | 265 | 355 | 442 | 530 | 885 | 1330 | 1730 | 2660 |

| PAN(AS) | 80 | 14-2 | 0.32 | 0.5 | 0.1 | 0.05 | 13 | 22 | 33 | 44 | 90 | 135 | 220 | 265 | 355 | 442 | 530 | 885 | 1330 | 1730 | 2660 |

| TPE | 110 | 3 | 0.7 | 0.7 | 0.1 | 0.02 | 13 | 20 | 30 | 40 | 85 | 125 | 205 | 250 | 330 | 413 | 495 | 826 | 1238 | 1650 | 1860 |

☆如何选择所需之除湿机的机型:为达到最佳效率,

请取干燥能力表的 80%,

对照所需的原料及干燥能力,即可寻得正确的机型

例如:欲干燥 80kg/hr 的 PET,则 ND-300 即为适当的选择